OUR PRODUCTS

Water Softener Plant

WATER HARDNESS exists in significant areas of the country. Water softeners remove hard

undesirable dissolved minerals that result in annoying white scales on fixtures, appliances and

piping. Softening the water produces immediate benefits - reduce usage of soap & detergent,

cleaner clothes, and better tasting food and beverages.

The Water Softeners are available in different sizes and materials, manually operated or fully Automatic, & ready to install. The Water Softening Plants are available as standard models or custom built versions for specific needs.

The Water Softeners are charged with a high capacity polystyrene bead cation exchange resin in sodium form. When hard water passes through this resin column, the hardness forming calcium and magnesium salts are replaced with sodium salts which do not posses any hardness properties. This softening process is continuous until the material is exhausted of sodium salts when it is regenerated with a solution of common salt.

Iron Removel Plant

Classic India Iron Removal Plant is a CSIR, GOI tested and approved treatment plant which works on oxidation based media technology. The maximum amount of iron in water in India is 19.96 PPM. The permissible limit of iron in water is less than 0.3 ppm as per BIS 10500. We also make hand pump attachment units. CSIR, Government of India has given very positive report on our product after vigorous testing of our product as per all the desired criteria.

* Classic India Iron Removal Plant is approved from Ministry of Drinking Water and sanitation Department Govt. of India.

Our plants remove iron upto 20 ppm from water and are available for capacities of 1000 LPH to 200000 LPH

Our unit converts ferrous to ferric state in water and requires no aeration tank

Our units are completely online and can work with solar pumps, overhead tanks and tube wells

Our units don’t require any extra electricity for working and can work on a very wide range of ph in water

Swimming Pool

Deals in swimming pool filtration plants of different sizes for residential pools, commercial swimming pools, and house pools. You can measure your swimming pool size on the basis of pool volume, water flow rate, and others before choosing a swimming pool filtration plant. Our swimming pool filtration plants are quality-tested and use filtration, disinfection, and recirculation of swimming pool water to make it clean. Classic India is ready to guide you through buying the best swimming pool filtration plant as per the dimensions of other needs.

Maintaining a swimming pool is a challenging task as you can be infected with skin diseases in case of insufficient cleanliness. The water in the swimming pool needs to be properly sanitized and filtered at regular intervals to maintain the water quality and avoid waterborne skin infections. The swimming pool is filled with water all the time and leaves, dust and debris, and others to alter its color and odor. The swimming pool filtration plant is polluted due to sweat, saliva, hairs, and ointments that give a suitable environment to propagate the virus, bacteria, and microbes.

Filtration System

Different water filters have different functions. Some can make your water taste better, while others can filter out harmful chemicals or germs. No single filter can keep every type of contaminant out of your drinking water, and not everyone needs a water filter.

The water that comes to your tap actually contains small quantities of many other substances. Some of these are beneficial, such as the appropriate amount of a disinfectant, like chlorine, that helps keep your water safe from germs and fluoride, which helps prevent tooth decay. Other substances that might be in water can be harmful, such as lead and the germ Cryptosporidium. Filters can remove both good and bad substances from your water. Depending on your circumstances, filtering your water might not be a good idea.

There are many different types of filters available, and it can be confusing to decide whether you need one or which kind is best for you. In many areas of the world, the water is not safe to drink, so filtration is one option to protect your health. Here are some steps to consider when determining whether you want to use a water filter, and if so, what type and functions best fit your specific needs and preferences.

Dialysis Water Plant

Appropriate water quality is one of the most important aspects of ensuring safe and effective delivery of haemodialysis. Haemodialysis may expose the patient to more than 300 lt of water per week across the semipermeable membrane of the haemodialyser. Healthy individuals seldom have a weekly oral intake of water above 12 lt. The near 30 times increase in water exposure to dialysis patients requires control and monitoring of water quality to avoid excesses of known or suspected harmful elements being carried in the water and transmitted to the patient.

The water to be used for the preparation of haemodialysis fluids needs treatment to achieve the appropriate quality. The water treatment is provided by a water pre-treatment system which may include various components such as sediment filters, water softeners, carbon tanks, micro-filters, ultraviolet disinfection units, reverse osmosis units, ultrafilters and storage tanks. The components of the system will be determined by the quality of feed water and the ability of the overall system to produce and maintain appropriate water quality.

The Food and Drug Administration (FDA) regulates dialysis water purification systems and classifies water systems, along with dialysis machines, as Class II medical devices (FDA, 2011). Class II devices require diligent tracking of critical components and a complaint investigation system in place. Class I devices include loosely regulated items, such as tongue depressors and Band-Aids, while Class III devices, such as high-flux hemodialyzers and implantable pacemakers, are stringently regulated devices and require tracking of all parts (even nuts and bolts) (FDA,2009).

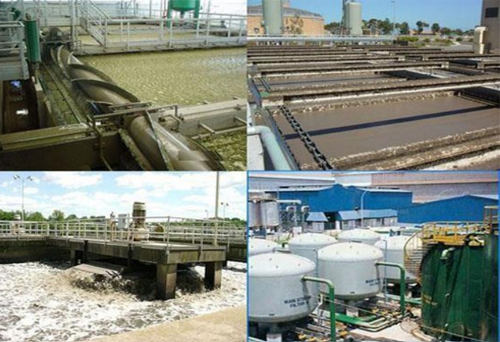

Effluent Water Plant

An Effluent Treatment plant is a unit plat where using multiple methods wastewater is treated for its reuse or safe disposal to the environment. This process reduces the demand of fresh water while keeping environment clean.

We develop Bio-Coagulation based Sequencing Batch Reactor ( BIO-CBSBR)Technology sewage treatment plants while ensuring we meet their specific sewage disposal and treatment needs and compliance requirements. Our sewage treatment plants (STPs) help you contribute to the environment through efficient sewage treatment. Additionally, our STPs are easy to operate and maintain. STPs, we specialize in include:

BIO-COAGULATION BASED SEQUENCING BATCH REACTOR (BIO-CBSBR) TECHNOLOGY

Membrane Bioreactor – MBR Sewage Treatment Plant

Sequencing Batch Reactor – SBR Sewage Treatment Plant

Moving Bed Biofilm Reactor – MBBR Sewage Treatment Plant

Packaged Sewage Treatment Plant

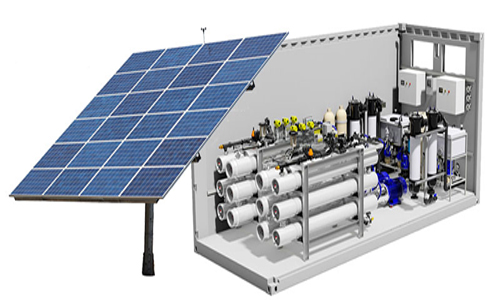

Solar Based Water Treatment

Solar water disinfection is a low technology, simple process of purifying water using solar energy and solar radiation. SODIS as a technology was first introduced in 1980 by Aftim Acra et al. from the American University of Beirut. The process involves contaminated water being filled in transparent PET or glass bottles which are then exposed to the sun for approximately 6 hours. The UV rays of sun eliminate the diarrhoea-causing pathogens, thereby making the water fit for consumption.

Solar water distillation uses a solar still to condense pure water vapour and settle out harmful substances to make clean, pure drinking water. This process is used when the water is brackish containing harmful bacteria, or for settling out heavy metals and also for desalination of sea water.

Solar water pasteurization involves the use of moderate heat or radiation to kill disease - causing microbes. This heat is provided from cookers that trap solar energy. This method has proven to kill bacteria, viruses, worms and protozoa.

Blow Moulding Machine

Blow molding is the process of inflating a hot, hollow, thermoplastic preform or parison inside a closed mold, so its shape conforms to that of the mold cavity. A wide variety of blow molded hollow parts, including plastic bottles, can be produced from many different plastics using this process.

The thermoplastic raw materials that are utilized within the blow molding process come in the form of small pellets or granules, which are first melted and formed into a hollow tube, called the parison. Blow molded parts can be formed from a wide range of thermoplastic materials, including:

Low Density Polyethylene (LDPE)

High Density Polyethylene (HDPE)

Polyethylene Terephtalate (PET)

Polypropylene (PP)

Polyvinyl Chloride (PVC)

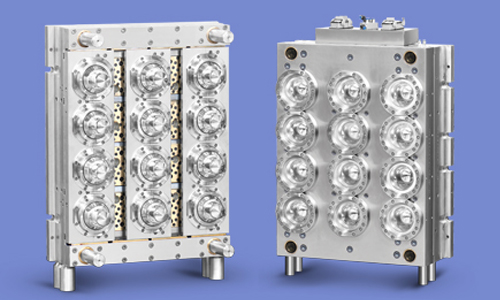

Hot Runner / Cap Mould / Hot Plate Preform

Acme Disys is a complete Preform and Cap Mold solutions provider involved in manufacturing of a wide range of products through advanced manufacturing methods and a customer centric approach.

With complete inhouse capabilities for designing, manufacturing, inspection and testing of the molds, the company manufactures Preform Molds upto 72 cavitation and Cap Molds ranging from 24 to 48 cavitation...

The company has made a mark in the design and development of a wide range of optimized Mold Systems. The company provides Preform Molds up to 72 cavitations, weighing from 4 to 750 grams and in neck sizes from 12 to 150 mm.

With successful track record, Acme continues to support the consumer base in the bottling segment of drinking water, aerated beverages, liquors and spirits, processed syrups and sauces, confectionery, edible oils, pharmaceuticals, cosmetics, shampoos, items of personal care, detergents, pesticides and industrial oils among others..

Injection Molding

Blow molding can be used to create numerous types of parts. Parts produced from the blow molding process are generally plastic, hollow, and thin-walled. These types of products are regularly used and are available in a bevy of shapes and sizes. Some of these types of blow molded parts, include:

Water & soda bottles, Shampoo bottles,Oil jugs, Milk containers, Storage tanks, Plastic drums, Tubs

Within the injection blow molding process, the material is injection molded. The hot material, still on the core pin, is then indexed to the blow molding station where it is blown into a bottle and allowed to cool. The bottle is then indexed to the next station and ejected. Injection blow molding allows more precise detail in the neck and finish (threaded) area than extrusion blow molding. Little improvement in physical properties is realized in the injection blow molding process since very little orientation occurs.

Water Filling Machine

Offering you a complete choice of products which include packaged drinking water system, industrial ro system, industrial reverse osmosis system, reverse osmosis plant, packaged drinking water plant and reverse osmosis system.

We offer Mineral Water Plant. Mineral Water Plant is mostly use in drinking water industries, food , beverages , pharmaceutical industries, chemical industries etc.Mineral Water Plant is start with raw water pump, sand filter, carbon filter, anti scalent dozing , mcf, high pressure pump, ozonation, uv system etc.

Industrial Reverse Osmosis System is to remove impurities from tap and brackish water. Its FRP membrane housing, Micron Cartridge Pre-filter, PLC control panel, high pressure switch, and low pressure switch, Permate and concentrate flow meters.

We are manufacture and supply a complete range of Drinking Water Plant .Drinking Water Plant is TURNKEY BASIC PROJECT. The system following equipment:

1) Filter Assembly(Sand/Cartridge/Bag Filter)

2) High Pressure Pump

3) Membrane with Housing

4) Storage Tank required

5) Fully Automatic and Semi Automatic Filling Machine

6) Pet Stretch Blowing Machine

8) Ink Jet Batch Coding Machine

9) Laboratory Set Up

10) ISI Certification

Sewage Treatment Plant

Our Sewage Treatment Plants cater in diversified areas such as Residential Complexes, Hospitals,

Schools & Institutions, Hotels & Resorts etc., to name a few

We have professional expertise to deal in the following Sewage Treatment Technologies.

Why Are Sewage Treatment Plants Required?

The first thought for anyone planning a new development should be getting connected to mains sewers. They are typically the most cost-effective and reliable method of dealing with your wastewater. However, getting a mains sewer connection isn’t always possible. In some scenarios, the distance from the nearest sewer or the layout of the land can make it impossible to have your property serviced by a mains sewer. That’s where sewage treatment plants and other alternatives come in. The operation of a sewage treatment plant means that you can have one installed almost anywhere, as long as you have an electrical connection.

Do Sewage Treatment Plants Still Need Emptying?

The purpose of a sewage treatment plant is to treat the wastewater as thoroughly as practically possible – and, even though such plants can often deal with more waste than a septic tank, they will still need emptying from time to time. Over time, sludge can also build up in the system, so it’s important that a treatment plant is regularly maintained at least once a year or as you are advised by the installer.

Waste Water Treatment Plant

Wastewater treatment is the process of converting wastewater – water that is no longer needed or is no longer suitable for use – into bilge water that can be discharged back into the environment.

It may be formed by a number of activities including bathing, washing, using the toilet, and rainwater runoff.

Wastewater is full of contaminants including bacteria, chemicals, and other toxins. Its treatment aims at reducing the contaminants to acceptable levels to make the water safe for discharge back into the environment.

Having said that, what exactly is wastewater treatment and how does it work? Well, that is what we are going to learn over the next couple of sections.

Blood Specimen Collection Tube

There are six commonly used blood collection tubes. These are the serum tube, coagulation tube, erythrocyte sedimentation rate tube, heparin tube, EDTA tube, and sodium fluoride tube.

Most blood collection tubes contain an additive that either accelerates clotting of the blood (clot activator) or prevents the blood from clotting (anticoagulant). A tube that contains a clot activator will produce a serum sample when the blood is separated by centrifugation and a tube that contains an anticoagulant will produce a plasma sample after centrifugation. Some tests require the use of serum, some require plasma, and other tests require anticoagulated whole blood.